Details

▶ Suit for standard milling cutters, aluminum processing cutters, arylic milling cutters, chamfering cutter and tap slotting.

▶ The multi-station and multi wheel group grinding ensure the quality and efficiency of tools.

▶ Front and rear doors of the grinder could easily unrestricted debugging and maintenance.

The protective cover keep safety when production.

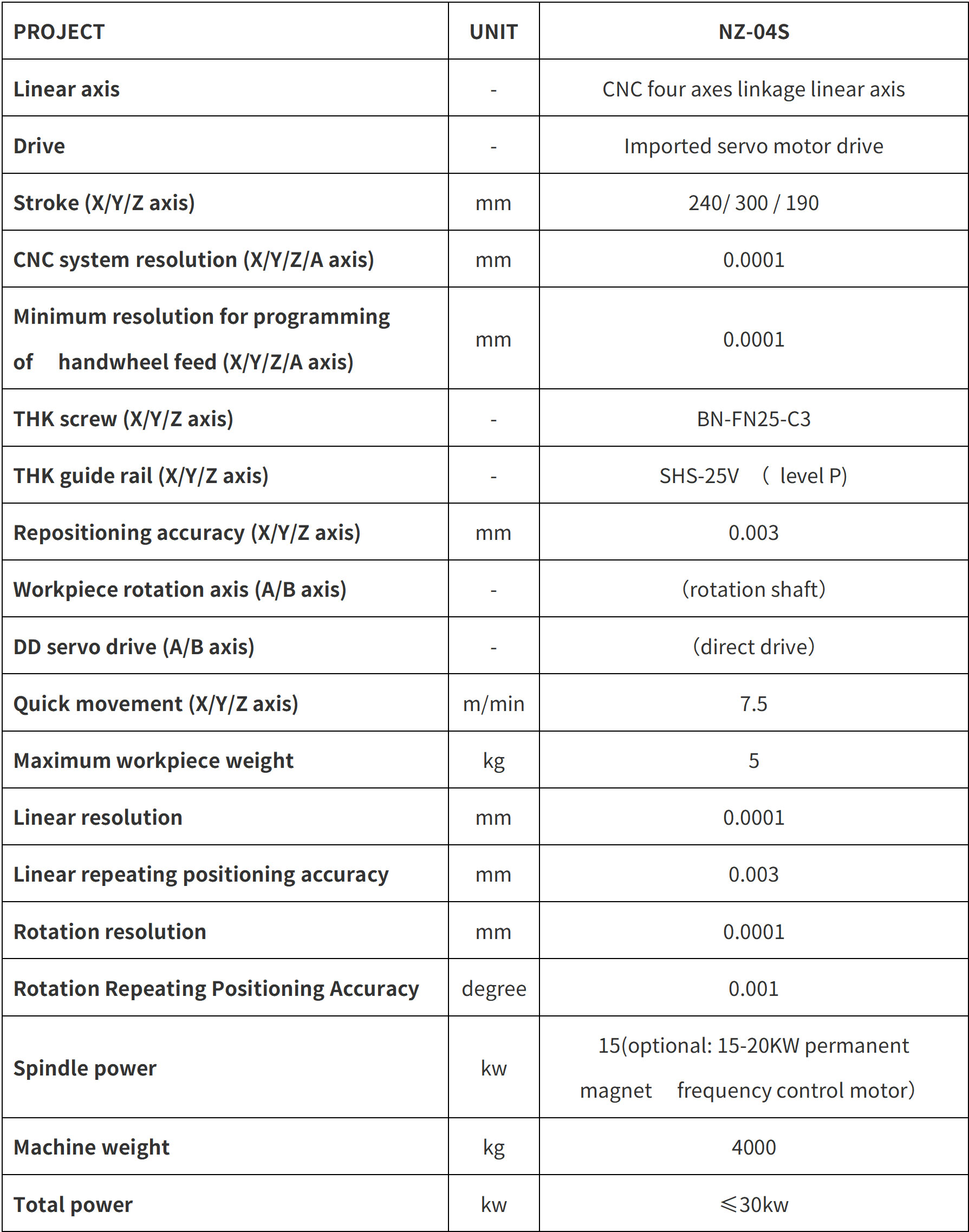

▶ All axes are equipped with high precision and resolution imported servo motors and screw guides for high quality and efficiency.

X-axis/Y-axis, horizontal straight CNC axis, Taiwan servo motor, THK precision ball screw, THK precision roller guide rail.

▶ Z-axis, vertical straight CNC axis, Taiwan servo motor, THK precision ball screw, THK precision roller guide rail.

▶ A-axis, rotating CNC workpiece axis, DD direct drive motor.

▶ Z-axis, increasing the angle rotation center of the column, and configuring an angle encoder to ensure repeated positioning accuracy when replacing different thread angles and adjusting the size efficiently.

▶ Marble overall.

▶ Sealed hood with painting for easy adjustment and maintenance.

▶ The CNC operation panel is installed upon the hood with magnetic easily movable handwheel.

▶ A special high-speed slotted electric spindle, which could be installed with one to three grinding wheels. It would be disassembled as a whole to the grinding wheel trimming machine.

▶The side and vertical shafts adopt Taiwan's high-precision direct connected electric spindle.

▶ The spindle motor adopt variable frequency control regulation.

▶ The machine is equipped with sealed tubular oil-proof fluorescent lamp.

▶ Installed with external automatic loading and unloading robet for increasing the lifespan. (Optional)