-

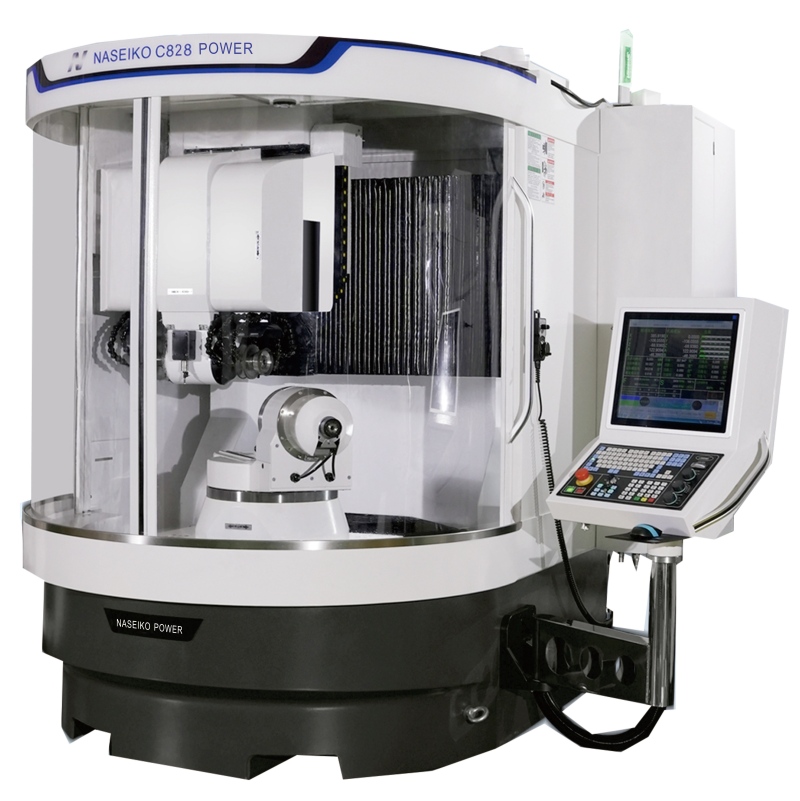

C828 Five-axis Five-linkage CNC Tool Grinder

Integral mineral casting bed, Japan servo motor and screw guide rail (heavy-duty roller type) and AB rotating shaft with high torque DD direct drive motor.

Contact Details

The permanent magnet constant torque spindle motor, dual grinding head structure and 360 degrees rotating of B-axis for non-standard cutting tools procession.

Designed upon the concept of German 5-axis CNC grinding machines.

Designed by integrating the practical experience and guidance. -

NT630 Five-axis Five-linkage CNC Tool Grinder

Integral mineral casting bed, Japan screw guide rail and AB rotating shaft with DD direct drive motor.

Contact Details

The permanent magnet constant torque spindle motor, dual grinding head structure and 360 degrees rotating of B-axis for non-standard cutting tools procession.

Designed upon the concept of German 5-axis CNC grinding machines.

Designed by integrating the practical experience and guidance. -

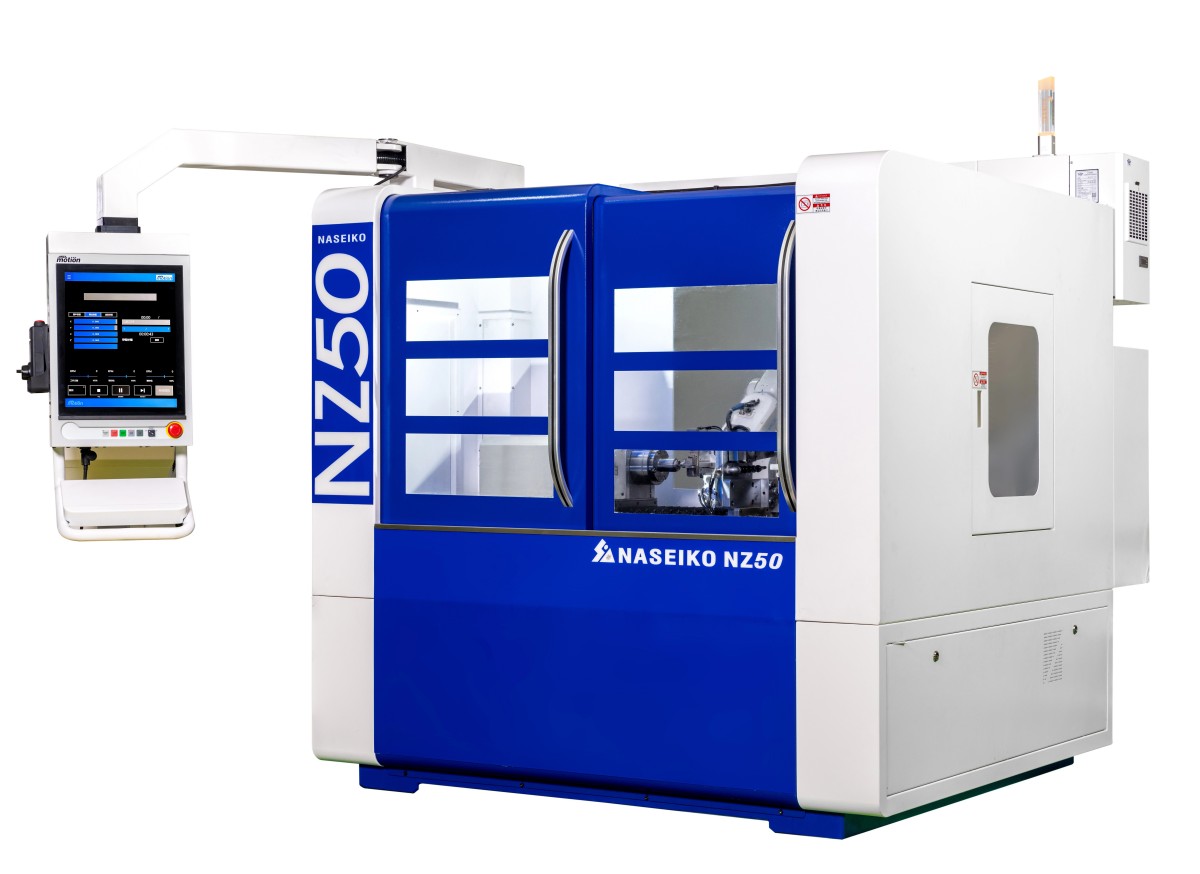

NZ-50 Five-axis Four-linkage CNC Step Grinder

The Five-axis Four-linkage (coarse and fine) CNC step grinder produced by our company is designed based on the design concept of the international advanced grinding machine company and the actual operating experience of domestic users, and is optimized and improved on the relevant basis. It is practical, economical and operational. ,maintenance, stability and efficiency are reflected.

Contact Details

The machine tool system adopts imported ANCA(anca system and software. In order to optimize the relative position relationship of the servo axes of the equipment, the X, Y, Z, and Z1 linear axes use imported -

NZ-518 Four-axis Three linkage CNC Grinder

The machine tool adopts an integral imported organic glass round door, which facilitates the unlimited operation and maintenance of the machine tool. The fully enclosed protective cover shell is in line with production safety. In order to cope with the production of special tools, the relative position relationship of the servo shaft of the equipment can be optimized, and the structure can correspond to the processing of a variety of tools. The X and Y axes:imported linear motors and screw rail, A axis: DD direct drive, which has high precision and resolution to ensure the high production e

Contact Details -

NZ-04S Four-axis Four-lingake CNC Grinding Machine

Suit for standard milling cutters, aluminum processing cutters, arylic milling cutters, chamfering cutter and tap slotting.

Contact Details

The multi-station and multi wheel group grinding ensure the quality and efficiency of tools.

Front and rear doors of the grinder could easily unrestricted debugging and maintenance.

The protective cover keep safety when production.

All axes are equipped with high precision and resolution imported servo motors and screw guides for high quality and efficiency. -

CNC Tool Grinding Machine C828mini for Carbide in 3C

Five-axis CNC tool grinding machines are advanced precision equipment designed for manufacturing and regrinding various complex tools. With their multi-axis capability, these machines are essential for processing intricate 3D shapes and precisely controlling tool geometry. They play a pivotal role in industries such as 3C electronics, medical devices, automotive, high-speed rail, aerospace, and precision tool grinding. Below are detailed applications in these fields:

Contact Details -

NZ-30 Three-axis Two-linkage CNC Tool Grinder

Integral mineral casting bed, Japan servo motor and screw guide rail (heavy-duty roller type) and AB rotating shaft with high torque DD direct drive motor.

Contact Details

The permanent magnet constant torque spindle motor, dual grinding head structure and 360 degrees rotating of B-axis for non-standard cutting tools procession.

Designed upon the concept of German 5-axis CNC grinding machines.

Designed by integrating the practical experience and guidance. -

C818 Five-axis Five-linkage CNC Tool Grinder

Integral mineral casting bed, Japan servo motor and screw guide rail (heavy-duty roller type) and AB rotating shaft with high torque DD direct drive motor.

Contact Details

The permanent magnet constant torque spindle motor, dual grinding head structure and 360 degrees rotating of B-axis for non-standard cutting tools procession.

Designed upon the concept of German 5-axis CNC grinding machines.

Designed by integrating the practical experience and guidance. -

NT618 Five-axis Five-linkage CNC Tool Grinder

Integral mineral casting bed, Japan screw guide rail and AB rotating shaft with DD direct drive motor.

Contact Details

The permanent magnet constant torque spindle motor, dual grinding head structure and 360 degrees rotating of B-axis for non-standard cutting tools procession.

Designed upon the concept of German 5-axis CNC grinding machines.

Designed by integrating the practical experience and guidance.

9 Records 1/1 Page