Details

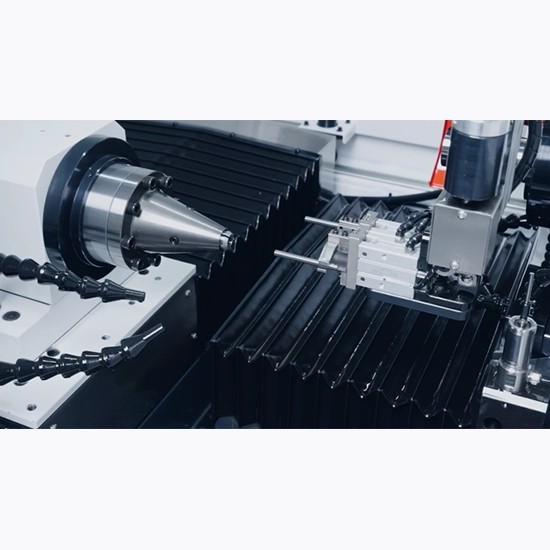

▶X axis, linear CNC axis, Taiwan servo motor, THK precision ball leadscrew, THK precision roller guide rail

▶Y axis, linear CNC axis, Taiwan servo motor, THK precision ball leadscrew, THK precision roller guide rail.

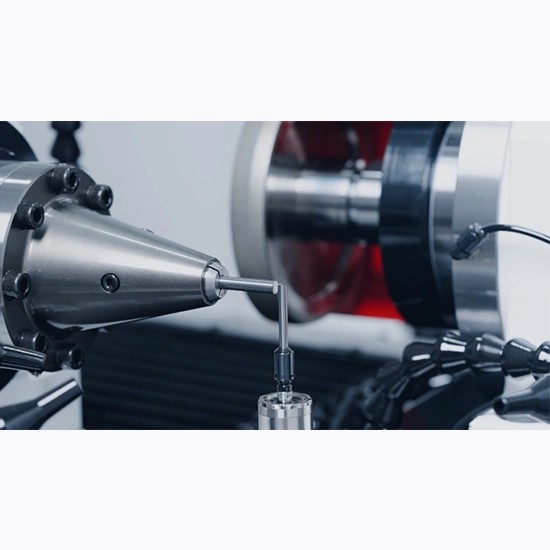

▶A axis, rotating permanent magnet workpiece spindle

▶Grinding wheel spindle: 15KW permanent magnet electric spindle

▶Integral marble bed body

▶Seal the cover, convenient to adjust the machine, paint, the cover can be removed as a whole, convenient maintenance

▶The CNC operation panel is installed on the hood, and adopts the mobile hand wheel with magnets for easy operation.

▶A special high-speed grooved electric spindle, can install one to two pieces of grinding wheel, can be dismantled to the grinding wheel dressing machine to repair the grinding wheel.

▶Frequency frequency control of spindle motor.

▶Install pipe sealed oil-proof fluorescent lamp in the machine.

▶Taiwan SYNTEC SCARL, robot automatic loading and unloading machine independent space installation, increase the service life of the robot.

▶Guide rail: Japan THK level P

▶The screw: Japan THK level C3

▶Servo motor: Taiwan SYNTEC Absolute value CNC system

▶Robot: Taiwan SYNTEC SCARL (four axis)